Overview

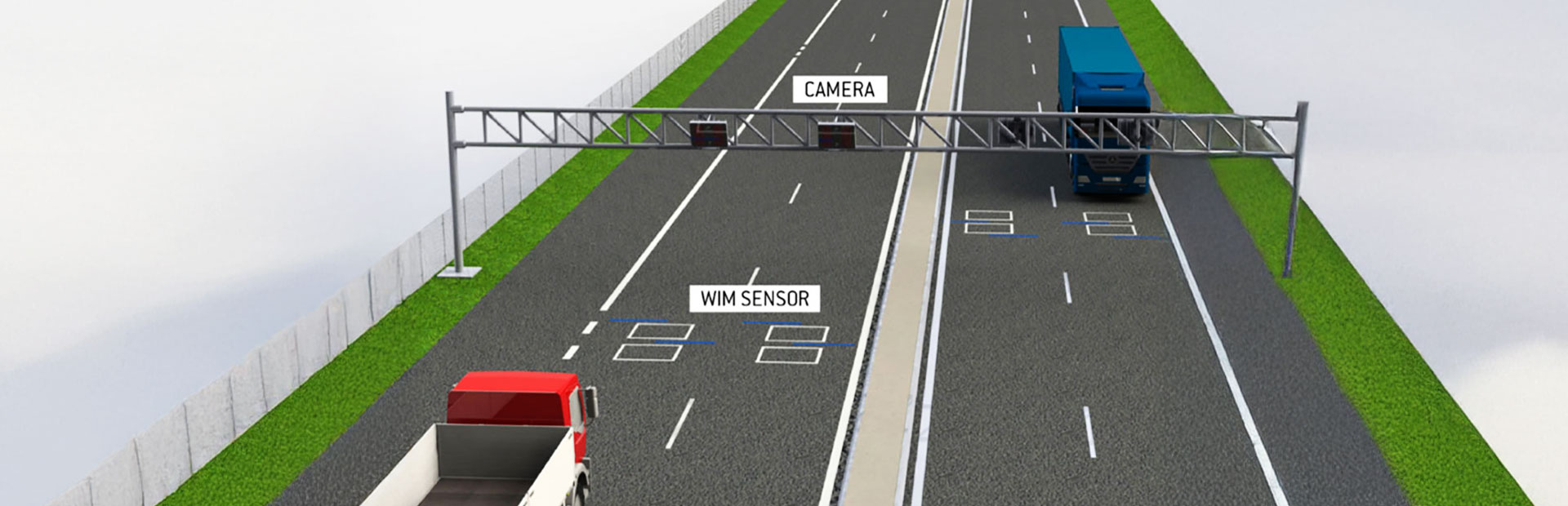

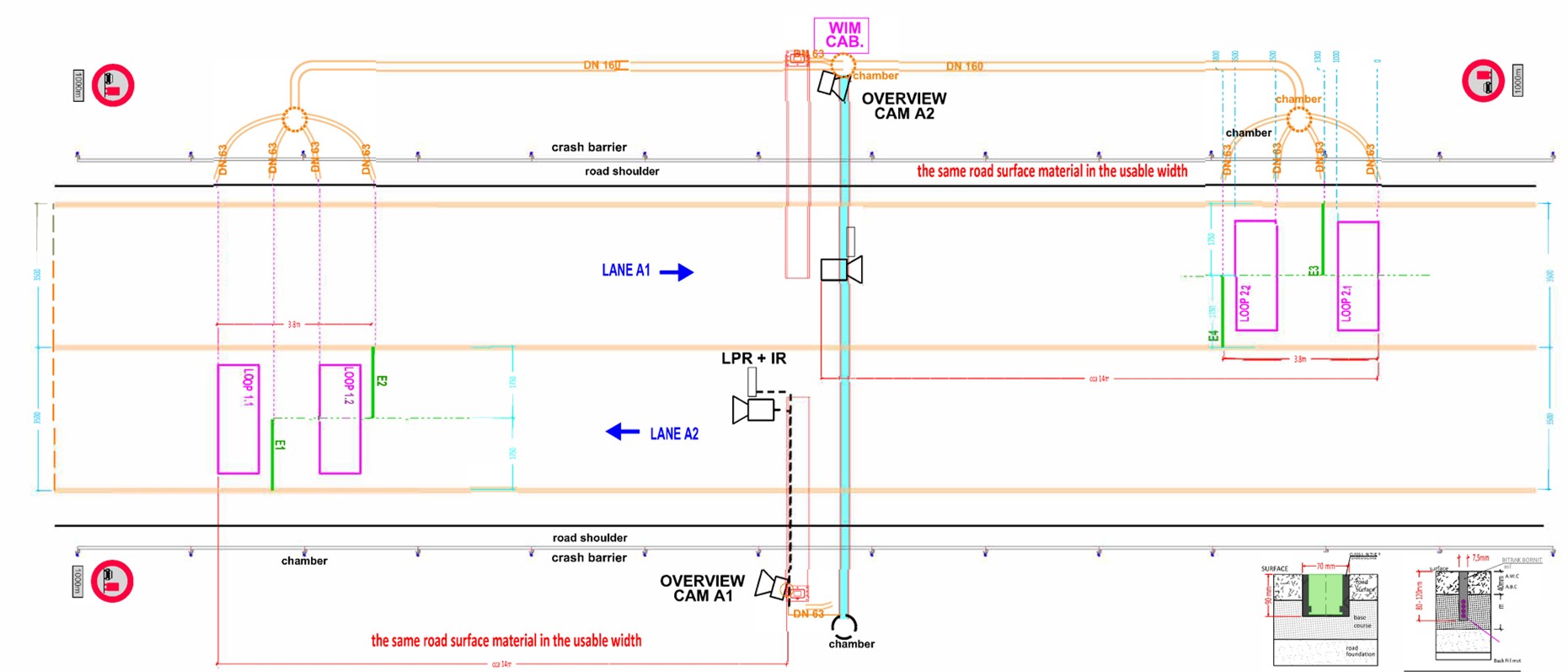

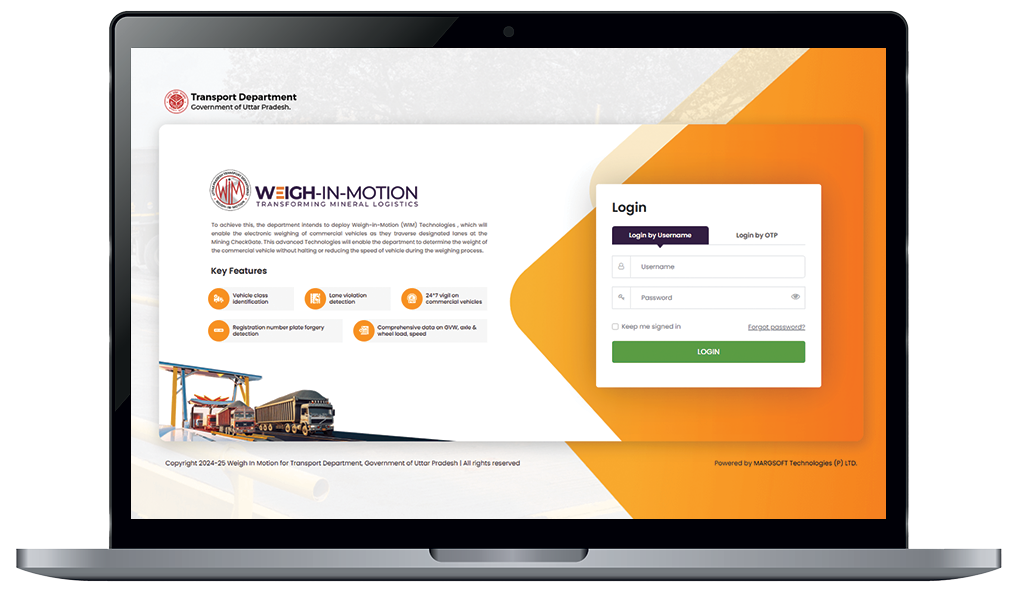

Establishment of Smart Enforcement System to Monitor Overloading Offences by installing Weigh-In-Motion System and Integration with the existing Mining Checkgate, Established by Directorate of Geology & Mining of the state.

Key Features

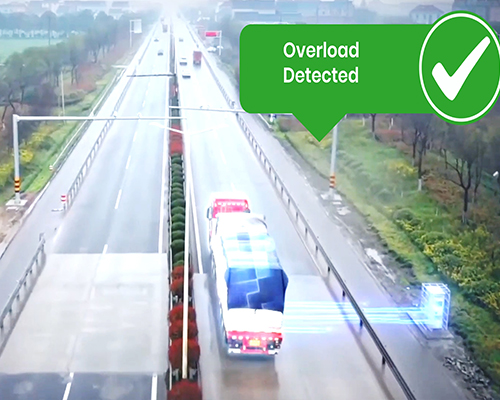

Weigh-in-Motion System to curb overloading system functions efficiently for vehicles traveling at speeds of up 20 to 80 km/h, capturing all necessary evidence to issue challans to violators.

Curbing pilferage and ensuring fair trade by integrating weigh-in-motion technology with the mining checkgate, leading to increased revenue and fair mineral transportation.

24*7 automated and transparent enforcement through online issuance of e-Notices, speed and lane violation detection to promote legal and safe transportation.